Bru Brewing: Discovering a Quality in Craft Beer

Crafting a beer worth drinking is an art in it’s own right. In a world looking for diversity and a people yearning for unique experiences, a new kind of dining scene has begun to emerge. The Gastro-Pubs, the Food Trucks, the Pop-up Restaurants, Micro-Breweries… The bold and the restless, where young chefs and craftsmen, cooks and brew masters dare to take chances. Small plates, restaurants based on a single dish, beer tastings, and where does it end… does it have to end? And exciting time in the wonderful world of cookery. A million different flavors… Ours for the taking. In Superior Wisconsin, a small group of craftsmen are taking to the Challenge of Brewing a Fine Beer worth tasting. Joel Weyenberg (Founder and Lead Brewer) and Collin Smith (Assistant Brewer) become the driving force behind Bru Brewing.

Young and determined Joel has begun studies in Food Systems and Technologies focusing on Food Sciences. After an Internship at Lake Superior Brewing, Joel set to work with Ideas and recipes of his own. Partnering up with Collin Smith, who has earned a Hotel, Restaurant & Tourism degree concentrating in Hospitality Management, the team has grown accustom to late night Brew Sessions, Trial & Error lessons learned only the hard way and the ever growing education that comes with establishing a Name.

A Bru of their Own; In a “Nut Shell”

Years of refinement, and months of nitpicking recipes lead to a freezing winter night, I find myself in possession of an invite to one of these “late night Brew Sessions.” I mean… I like Beer, so Why Not. In Wisconsin, Home Brewing is nothing new, it’s a way for the old men to pass the Winter months and Drink cheaper later in the year. I enthusiastically except the offer and bring a camera for kicks.

In all sincerity, I am instantaneously lost in the Brew Chat happening around a Bunsen burner as the production begins to take off. The Mise En Place is exact, everything from ingredients to supplies are in place. And as I watch Joel kick into Brew Gear, Collin places a beer in my hand and begins to talk Shop. I take a swig of a beautifully creamy, rich stout. Its delicate and full bodied, filling my mouth like a glass of chilled milk.

I interrupt Collin, “This is a Scrumptious beer… not sure that I’ve had it, Who makes it?” I ask in a naïve tone, fully expecting to hear that it is some form of a seasonal Guinness or Maybe even the stout belonging to a Sierra Nevada type brewery. Collin smirks… “That’s a Chocolate Milk Stout, from “Our” Twelve Beers of Christmas. We called it Donner’s Addiction.”

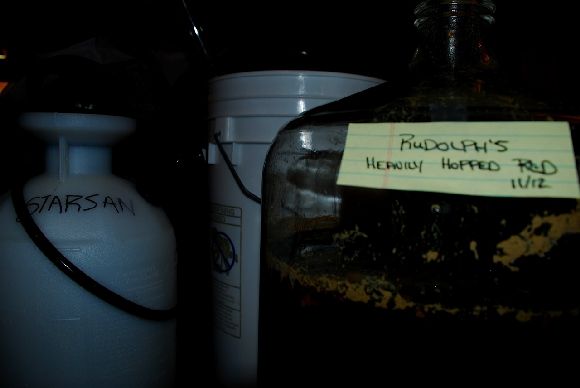

“Huh…” Bru had captured my attention. As I watch the Process unfold before me in a garage… I couldn’t help but feel dumbfounded, this stout likely started as a brainchild in this most humble production room.

“Well you want to heat the strike water (beginning addition of water) to mash (saturate and steep) your grains for about an hour so that the Starches are fully converted to sugar. Then you want to start Sparging (rinsing the grain in hot water extracting all possible sugars) and collecting the Wort (the sugar water… aka: unfermented young beer) in the Brew Kettle” Collin rattles off the process as if he has been through it a million times. I ask question after question after question… until it is broken down into terms that I can relate to.

“Then bring the wort to a boil at about 211°F…” Collin continues with the process explaining the effects of adding hops and the reasoning behind adding them in different stages of the brewing process, “These hops that I am adding now will determine the bitterness and depth of the beer… later on I will add some for the Floral notes and Aromatics.” He finishes while handing me a Raspberry Wheat beer that they had named, Rubus Strigosus… Clever.

When the boiled wort is ready, the vessel is changed to a fermentation tank in which the Wort is then chilled to a temperature of 80°F. Yeast is then pitched in on top and aerated into the Wort. The vessel is then aged for five-7 days at a temperature of 65-70°F. With the use of gelatin the beer is clarified and rests for several more days until the beer becomes translucent… Crystal clear. Final step is to keg or bottle, age and enjoy.

A bottling get together, a week in the making!

Fist after fist, I find an appreciation for specialty beers. Blown away by the talent coming from this “Late Night Brew Session” Crisp, Robust, Citrus, Cardamom… Unlike any beer I have ever tasted, and the Quality was merely elevating with a slight buzz.